MIL-DTL-3390H

(Copies of these documents are available at https://www.sae.org/ or from SAE International, 400

Commonwealth Drive, Warrendale, PA 15096-0001.)

2.4 Order of precedence. Unless otherwise noted herein or in the contract, in the event of a

conflict between the text of this document and the references cited herein, the text of this document

takes precedence. Nothing in this document, however, supersedes applicable laws and regulations

unless a specific exemption has been obtained.

3. REQUIREMENTS

3.1 First article. When specified (see 6.2), a sample shall be subjected to first article

inspection in accordance with 4.2.

3.2 Materials. The materials specified shall conform to applicable specifications and

requirements specified herein. Commercial tolerances apply to wire diameters.

3.2.1 Copper alloy casting. The copper alloy (brass) castings shall conform to copper

alloy UNS no. C85700 in accordance with ASTM B584.

3.2.2 Brass sheet or strip. The brass sheet or strip shall conform to copper alloy UNS no.

C26000 or C26800, rolled temper half hard in accordance with ASTM B36/B36M.

3.2.3 Wire, copper alloy. The copper alloy (brass) wire shall conform to copper alloy

UNS no. C46200 or C46400, temper half hard or light annealed in accordance with

ASTM B21/B21M.

3.2.4 Steel wire. Steel wire shall conform to AISI steel number 1006, 1008, or 1010,

bare, annealed-in-process in accordance with ASTM A853.

3.2.5 Malleable iron. Malleable iron castings shall be black, ungalvanized, with a yield

strength of 35,000 pounds per square inch (psi) and demonstrate an elongation of 18 percent

minimum with a 2-inch test sample tested in accordance with ASTM A47/A47M.

3.2.6 Nickel-silver alloy. Nickel-silver alloy castings shall conform to table I for

chemical composition when tested as specified in 4.3.3.

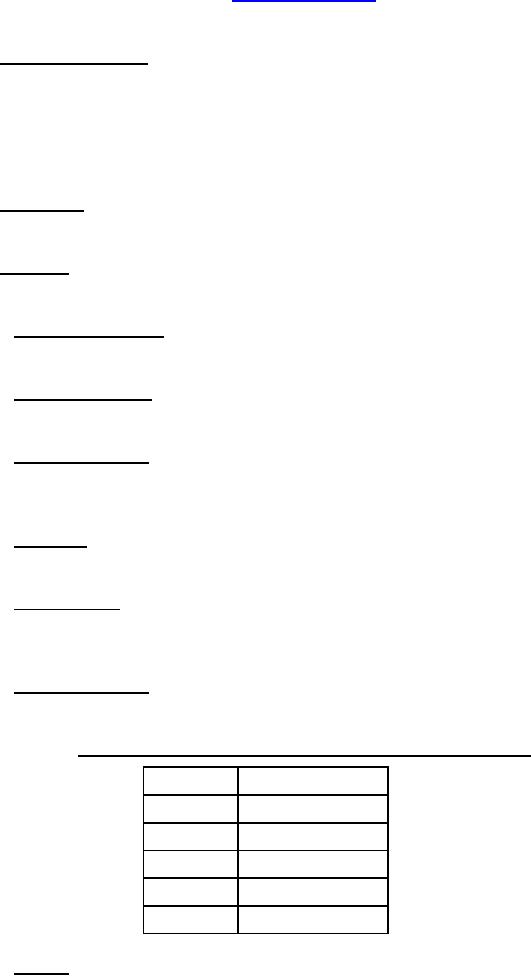

TABLE I. Chemical composition, copper-nickel-zinc (nickel silver) alloy.

Material

Percent

Copper

55.0 to 64.0

Nickel

18.0 (min)

Zinc

Remainder

Iron

0.35 (max)

Other

0.25 (max)

3.2.7 Enamel. The enamel shall be semi-gloss enamel alkyd conforming to MPI #94.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business