MIL-DTL-3390H

coating lacquers or other materials. The resultant surface gloss shall not exceed that of

FED-STD-595/27038, semi-gloss black, by visual comparison.

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are

classified as follows:

a. First article inspection (see 4.2).

b. Conformance inspection (see 4.3).

4.2 First article inspection. When first article is required (see 6.2), the dee rings shall be

presence of any defect shall be cause for rejection of the first article.

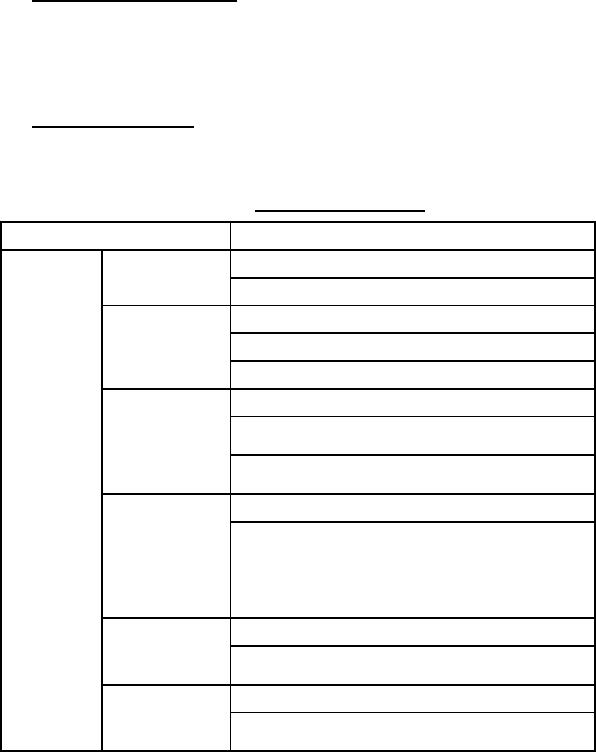

TABLE II. End item visual defects.

Examination

Defect

Finish

General

Not type specified

Evidence of corrosion

Black chemical

Color not as specified

Finish not clean and uniform

Area of no finish or finish discolored

Enamel

Area of no film or color not as specified

Separation of color or finish rough (i.e., lint, dust,

dirt, or other foreign matter embedded in finish)

Finish not continuous, smooth, and adherent (i.e.,

orange peel, wrinkles, drops, streaks)

Coating omitted or area of no coating

Coating not smooth, uniform, fine-grained, or not

Zinc, chromium,

tightly adherent (i.e., flaky, blistered, or peeling); or

and cadmium

coating is scratched, stained, discolored, shaded,

plated

broken, or cut through or is not free from pits,

modules, or indications of burning

Not smooth, lusterless, or semi-gloss black

Plastic

Gloss exceeds FED-STD-595/27038 when

compared visually

Polish not bright

Polished finish

Buff drag, cloudy, hazy, or mottle, finish clearly

noticeable

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business