MIL-DTL-3390H

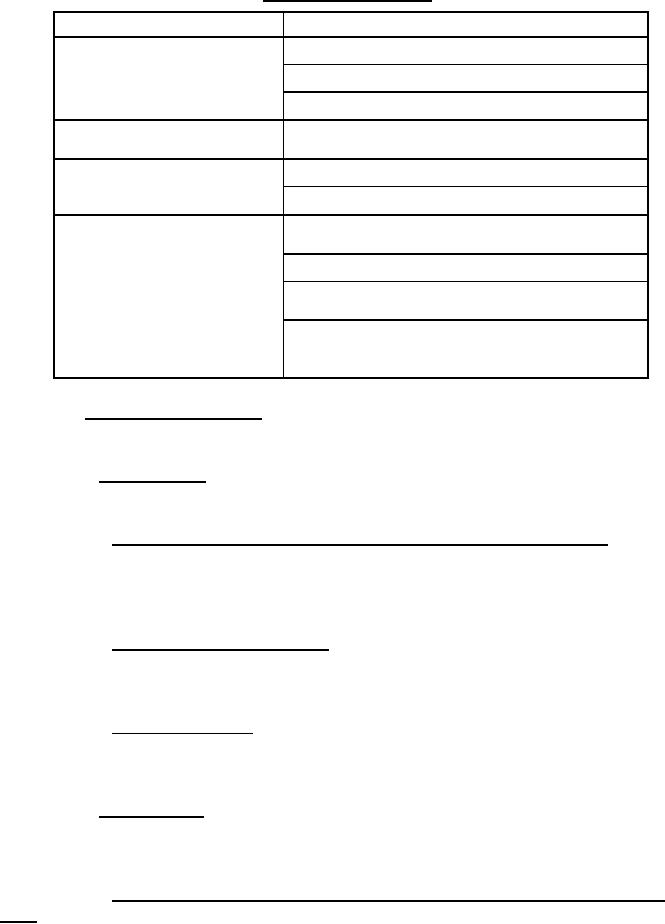

TABLE II. End item visual defects - Continued.

Examination

Defect

Construction and workmanship

Sharp edge or projection that may cause injury

Cracked, broken, bent, malformed, or damaged

Pronounced tool or forming marks

Casting

Miscast, incomplete, or contains blowholes or

evidence of porosity

Roller (when applicable)

Does not turn freely

Joint not butted

Workmanship of welds

Weld or brazing missing, unless welding is not

or brazing

required

Completely broken or not fused

Cracked, partially broken, incomplete, or evidence

of poor fusion or burn through

Evidence that weld contains gas pockets or has been

undercut or that excess flux or spatter has not been

removed

4.3 Conformance inspection. Unless otherwise specified herein, sampling for

conformance inspection shall be performed in accordance with ASQ Z1.4.

4.3.1 Lot definitions. The lot definition is directly related to the stage of manufacturing

at which a sample is taken.

4.3.1.1 Material composition test for copper-nickel-zinc (nickel silver) alloy. For

purposes of sampling, a lot shall consist of material taken from one manufacturing run. Each test

sample will be 4-ounces (oz). The lot size will be determined by dividing the weight of the lot

by 4 oz. Example: a 100 pound lot will be considered to have a lot size of 400.

4.3.1.2 In-process visual examination. The lot size shall be the number of in-process

rings of one configuration, class, and size, manufactured using the same materials and processes.

The lot shall be unfinished rings without rollers.

4.3.1.3 End unit inspection. The lot size shall be the number of finished rings of one

configuration, class, size, and style if applicable, manufactured using the same materials and

processes.

4.3.2 Sampling plan. Unless otherwise specified, sampling procedures for conformance

inspections and examinations shall be in accordance with 4.3.1 and ASQ Z1.4, inspection level

S-3. Acceptance quality limits (AQL) will be as specified in the contract (see 6.2).

4.3.2.1 Sampling for material composition test for copper-nickel-zinc (nickel silver)

alloy. A random sample of 4 oz test samples shall be selected from each lot and subjected to the

inspection specified in 4.3.3.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business